Ok, now I'm ready to swap mobo's and display screen from one tablet to the other one (the mobo from the 2nd tablet onto the display unit of the 1st tablet), so here are the tools/materials I have to work with:

The pliers are to cut the black & red wires,

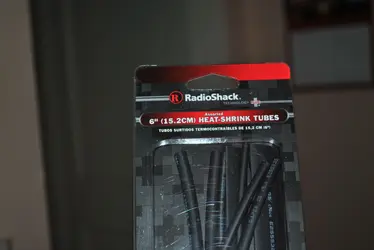

the heat shrink tubing is to shield the wires (after they're soldered) from touching and causing a short,

heat gun I got to shrink the shrink tubing

before I do anything, I have questions:

and I have 2 kinds of solder - the coil and the tube, which should I use to solder the wires?

you need flux core or some flux, otherwise the solder wont stick to the wires

and the bare rigid display cable (running alongside the display unit), should I cut it with these pliers?

dont know

At what area/place should I cut it to ensure easy placement/soldering once the mobo has been swapped?

dont know

How to I apply the solder?

i always heat the gun then apply the solder to the tip

which type of solder should I use, the coil or the tube?

already answered

how much solder should I use to join the ends of the wires and the display cable?

as little as possible to firmly join the wires, you dont want a big glob or ball hanging off. wont hurt anything its just too much.

also, just touch the solder on the tip of the gun to the wires for a few seconds at most, it should draw right into the wire almost as soon as you touch it

do I have to put a support under the wires and the display cable while applying solder so the wires/display cable won't get bond to the back (silver part) of the display unit?

i would try and find a small piece of dense plastic to put under the wires, to protect the display

how/what type of supports am I supposed to use for the wires?

^^^

how to I insert a support under the display cable?

not sure without seeing the situation

what setting do I put the heat gun on to shrink the shrink tubing (temperature)?

that heat gun is way too big for what you are doing. i would be scared of heat damage to the components.

if there is room, i would just try to get the smallest shrink possible and not shrink it. use a small piece of tape to hold it over the joint.

if you must shrink it, i would get one of those crack lighters (i dont know what there called really), this way you have a small concentrated heat source that you can easily direct onto the shrink.

how am I supposed (haven't a clue/never used a heat gun before) to use this heat gun to shrink the tubing?

answered

how long am I supposed to blow the heat gun on this shrink tubing so it'll be properly shrink?

you should see the tube shrinking, do it just long enough that the tube is small enough so it wont easily slide on the wires any more.

also, after soldering, before sliding the tube over the joint, try to wipe any excess flux off the wires otherwise the tube may slide around easily after shrunk.

how do I test the tablet after I've soldered everything to ensure I've soldered correctly before applying the shrink tubing?

not sure, but as long as the wires are connected firmly any issue you have wont be from the joint.

am I supposed to apply shrink tubing on the display cable after it's soldered (once the swap is completed)?

i cant say without seeing it. if it is an insulated cable then yes.

if its not insulated then no, although some cables may appear to be bare but actually are not. some wires are coated with an insulating coating, i would almost have to see it in person to determine if thats the case. if your cable has this coating, that causes another problem. the coating will need to be burned off first or the connection will never be good. again something i would need to see, but i usually use a lighter to burn it off, assuming you can do it without damaging any components.

hopefully you dont have that type of wire and none of that will apply to you.

this is all very new to me, hence all these questions.

I think I've asked all the questions I have to know, this is all I can think of at the moment.